3D laser cutting technology is widely used in the new energy vehicle (NEV) industry, primarily for high-precision processing of complex metal components. This technology utilizes high-energy laser beams to achieve rapid material cutting and is suitable for various metals, including aluminum alloys, high-strength steel, and copper alloys.

In battery manufacturing, 3D laser cutting is applied to process battery trays, enclosures, and conductive connectors. Battery trays require precise cutting of cooling holes, mounting holes, and edge contours, where laser cutting ensures smooth edges, eliminates burrs, and maintains sealing integrity. Conductive connectors demand extreme cutting accuracy, and laser technology minimizes thermal distortion while preserving electrical conductivity.

For vehicle body production, 3D laser cutting is ideal for processing aluminum-steel hybrid materials. To reduce weight, NEVs often use aluminum alloy or hot-formed steel components such as crash beams and A/B pillars. Unlike traditional stamping, which requires custom molds, laser cutting directly follows 3D models, adapting to complex curvatures and shortening production lead times.

Motor and electronic control system housings, end covers, and other components also require high-precision hole cutting and edge trimming. Laser cutting effectively handles intricate features like cooling channels and mounting holes on complex surfaces, ensuring assembly accuracy and thermal management. Additionally, small metal parts such as seat frames and charging port brackets can be rapidly formed via laser cutting to accommodate design variations across vehicle models.

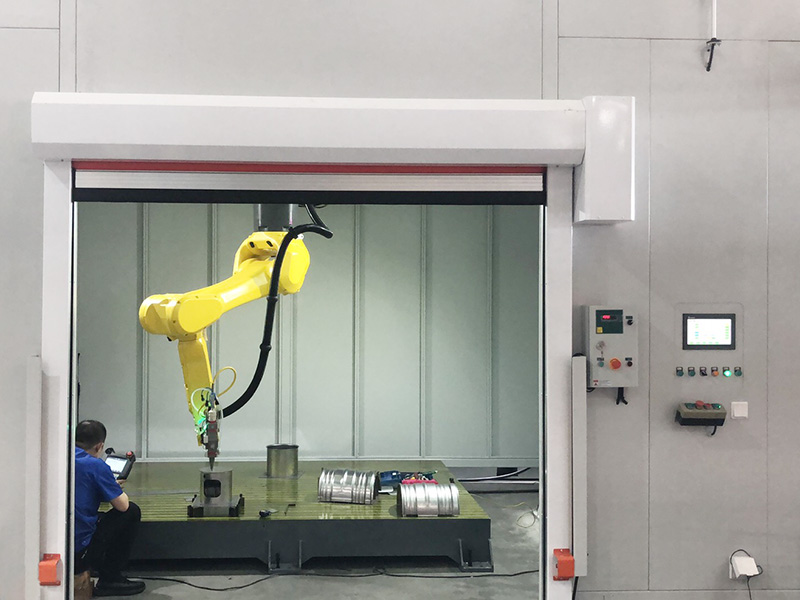

Dade Heavy Industry's main business includes digital robot workstations, industrial welding robots, robot application systems, various digital inverter welding machines, 3D flame/plasma/laser cutting machines, automatic welding equipment, and arc welding robots. The company takes technology as the guide, independent products as the core, and leverages its talent advantages to accumulate a large number of core technologies and products in the fields of robotics, lasers, etc. It has obtained more than 20 provincial and municipal science and technology projects, obtained more than 30 projects, and provided customers with nearly 10000 sets of products in 50 series, 200 specifications, and nearly six categories. The products are sold to 30 provinces, autonomous regions, and municipalities directly under the central government nationwide, and exported to Southeast Asia, the Middle East, Japan, Europe, America, and other regions. Widely used in various fields such as petrochemicals, electricity, metallurgy, shipbuilding, locomotives, automobiles, construction, engineering machinery, etc.

Comments on “dade 3D laser cutting in new energy vehicle manufacturing”